Introduction

In the world of metal casting, the backcasting room is a term often mentioned but not always fully understood. This essential space plays a crucial role in the production process, ensuring that castings are made to precise specifications and high standards. In this article, we’ll explore what the back casting room is, its functions, the equipment found within, and why it’s indispensable to the metal casting industry.

What is the Back Casting Room?

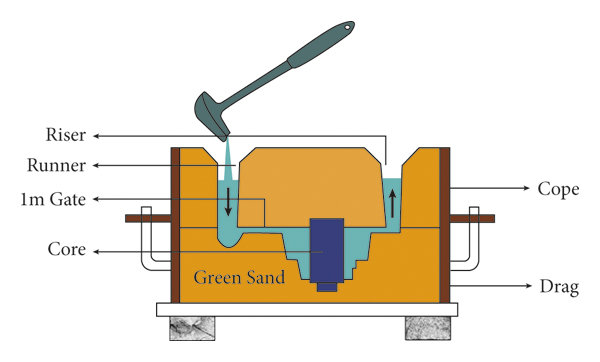

The back casting room, sometimes referred to as the finishing room, is a dedicated space in a foundry where the final stages of the casting process take place. After molten metal is poured into molds and allowed to solidify, the raw castings are transferred to the back casting room for finishing touches. This room is integral to ensuring that the final products meet quality standards and are ready for use in various applications.

Functions of the Back Casting Room

Cleaning

One of the primary functions of the back casting room is cleaning. After casting, the metal pieces often have excess material, known as flash or burrs, that need to be removed. This process involves various techniques, such as grinding, blasting, and sanding, to produce a smooth and clean surface.

Inspection

Quality control is a critical aspect of the casting process. In the back casting room, each piece undergoes thorough inspection to detect any defects or irregularities. This step ensures that only high-quality castings proceed to the next stage of production or are shipped to customers.

Heat Treatment

Some castings require heat treatment to achieve the desired mechanical properties. The back casting room is equipped with furnaces and other heat treatment equipment to alter the metal’s structure, improving its strength, hardness, and ductility.

Machining

Machining involves precisely cutting, shaping, or finishing the castings to meet specific dimensions and tolerances. The back casting room is often equipped with lathes, mills, and other machining tools to achieve these precise measurements.

Painting and Coating

To enhance the durability and appearance of castings, they may be painted or coated in the back casting room. This step involves applying protective layers that can prevent corrosion, improve wear resistance, and provide aesthetic appeal.

Key Equipment in the Back Casting Room

Grinding Machines

Grinding machines are used to remove excess material and smooth out rough surfaces on the castings. They come in various types, including bench grinders, belt grinders, and angle grinders.

Blast Cabinets

Blast cabinets use abrasive materials propelled at high speeds to clean and polish the surfaces of castings. This process, known as sandblasting or bead blasting, is essential for removing surface contaminants and preparing the metal for further finishing.

Inspection Tools

Inspection tools such as calipers, micrometers, and coordinate measuring machines (CMMs) are used to measure the dimensions and tolerances of castings accurately. Non-destructive testing (NDT) methods like ultrasonic testing and X-ray inspection are also employed to detect internal defects.

Heat Treatment Furnaces

Heat treatment furnaces are essential for altering the physical and mechanical properties of metals. These furnaces can perform various processes, such as annealing, quenching, and tempering, to achieve the desired characteristics in the castings.

Machining Tools

Machining tools, including lathes, milling machines, and drill presses, are used to shape and finish the castings to precise specifications. These tools are crucial for achieving the required dimensions and surface finishes.

Importance of the Back Casting Room

Quality Assurance

The back casting room is vital for maintaining high quality standards in metal casting. By thoroughly cleaning, inspecting, and finishing each piece, foundries can ensure that their products meet customer specifications and industry requirements.

Efficiency and Productivity

A well-equipped back casting room enhances efficiency and productivity in the casting process. By centralizing finishing operations in one space, foundries can streamline their workflows, reduce production times, and minimize costs.

Customization and Flexibility

The back casting room allows for customization and flexibility in the casting process. Foundries can perform various finishing operations to meet specific customer requirements, from altering dimensions to applying specialized coatings.

Challenges and Solutions in the Back Casting Room

Safety Concerns

Working in the back casting room involves handling heavy machinery and hazardous materials, posing safety risks. Implementing strict safety protocols, providing proper training, and using protective equipment can mitigate these risks.

Maintaining Equipment

Regular maintenance of the equipment in the back casting room is crucial to prevent breakdowns and ensure smooth operations. Establishing a maintenance schedule and performing routine checks can help keep the machinery in optimal condition.

Conclusion

The back casting room is a critical component of the metal casting process, providing essential services such as cleaning, inspection, heat treatment, machining, and coating. By understanding its functions and the equipment involved, foundries can enhance their production processes, ensure high quality standards, and meet the diverse needs of their customers. Whether you’re a seasoned professional or new to the industry, appreciating the importance of the back casting room can lead to better outcomes and more successful casting operations.

FAQs

What is the back casting room? The back casting room is a dedicated space in a foundry where the final stages of the casting process, such as cleaning, inspection, and finishing, take place.

Why is cleaning important in the back casting room? Cleaning removes excess material and smooths surfaces, ensuring the final castings meet quality standards and are ready for use.

What types of equipment are found in the back casting room? Key equipment includes grinding machines, blast cabinets, inspection tools, heat treatment furnaces, and machining tools.

How does the back casting room ensure quality? By performing thorough inspections and using precise finishing techniques, the back casting room ensures that only high-quality castings proceed to the next production stage.

What challenges are associated with the back casting room? Challenges include safety concerns and the need for regular maintenance of equipment. Implementing safety protocols and maintenance schedules can address these issues.